Weishi Inspection Tool Testing Center - Current

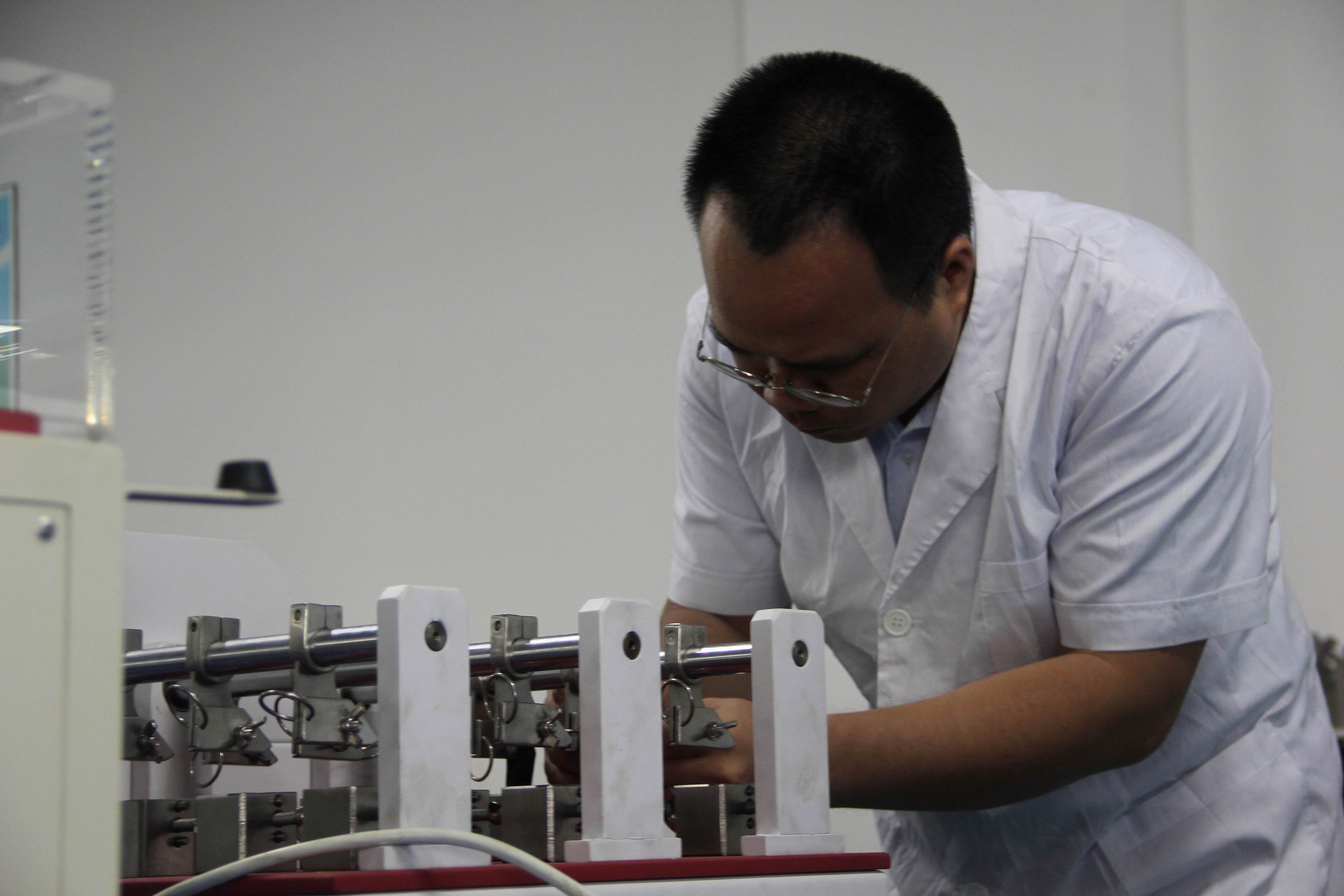

Weishi Inspection Tool Testing Center

Development of 10kA Strong DC Current Standard Source

Direct current is widely used in important industries such as power systems, industrial production, aerospace, high-speed rail locomotives, etc. In scientific research such as nuclear energy, metal electrolysis, and high-energy physics. It requires several thousand amperes or even more. At present, the measurement methods for large DC current include shunt method, DC transformer method, current comparator method, Hall current sensor method, and other magnetic methods. The accuracy of measuring high DC current will directly affect the measurement of DC energy.

In China, the flow value transmission system of DC power has not been established yet, so it cannot be said to be efficient and energy-saving. The strong DC current standard source proposed in this article has a current output capacity of 10 kA and an annual rate of change of 100 ppm/a. Its core consists of a high stability regulator and a broadband current comparator, with a short-term stability of 10 ppm/min. This provides a basis for establishing a large DC current measurement value transmission system and detection standards.

1.10 kA Strong DC Current Standard Source

1.1 Main characteristics of instrument calibration standard source

(1) The standard source consists of computer software, operating console, 18 channels of 600 A current source, voltage measurement module, etc* The output is 10 kA, continuously adjustable, and the output voltage is 4 V.

(2) 18 independent current sources: 18 independent current sources can be independently controlled, and the system architecture is flexible. Current output range: 0~600 A; Output stability: 0.002%/min; Annual accuracy: 0.005%, adjustment accuracy: 0.005%.

(3) The distributed power system with multiple switch power supplies in parallel has the advantages of large output capacity, high efficiency, and high reliability, which are the main factors ensuring high current output. The switch mode power supply used can meet the requirements of safety standards such as EN/UL60601 (including low leakage current and enhanced isolation requirements), as well as the B-level requirements of electromagnetic interference (EMI). The output power can be guaranteed to reach 50% of the rated power.

(4) Reliable protection system. It has a comprehensive overvoltage, overcurrent, and current open circuit protection system. If one of the current sources fails, it will not affect the normal operation of the other current sources.

1.2 10 kA standard source

Main features introduction:

(1) Computer automatic detection software: communicates data with the lower computer through RS232. Perform data processing, report printing, data saving, etc.

(2) Console: It is a bridge between hardware devices and computers for communication. It can be connected to a computer for fully automatic calibration, or it can be controlled separately from computer software for semi-automatic calibration.

(3) 18 channel current source: It is the core of the entire system. It consists of a 32-bit microprocessor, EEPROM, FPGA, switching power supply, PWM, driver and amplifier module, current comparator, A/D and D/A, various communication interfaces, buttons, alarm, power module, etc.

(4) Busbar: Plays the role of a busbar. Made of thicker copper plates, it has fast heat dissipation and can withstand large currents in a timely manner.

2. 600 A current source

The accuracy of a single current source is the key to ensuring that the entire device serves as a high current measurement standard. The following text will analyze the principle and technical difficulties of a single 600 A current source.

2.1 Working principle

(1) Power supply: The 220V mains power is converted into DC voltage through a transformer to supply power to the entire system. On the other hand, it is shaped and filtered to become a DC power supply, and then pulse modulated and output through PWM.

(2) DC current output control: After receiving the console command, the 32-bit microprocessor transmits it to the FPGA through the SPI communication interface. The FPGA then controls the D/A digital to analog converter to output a voltage reference signal and transmit it to the integrator. This signal, along with the feedback signal, is transmitted to the integrator for time τ to output a stable voltage signal. This voltage signal controls the amplitude of the square wave signal generated by the pulse width modulator PWM. The square wave signal is then passed through the power amplifier to drive the current amplifier module to output a large DC current. After filtering, the current flows through the wideband DC comparator. The broadband comparator converts the high current into a small current according to the designed ratio standard, and the small current is converted into a voltage signal through the I/V conversion circuit. This voltage signal enters the feedback circuit and feeds back to the integrator, forming a closed-loop negative feedback system. On the other hand, it enters the AD sampling circuit to record the current actual output value. The time for establishing system balance shall not exceed 1 μ s.

2.2 Technical difficulties and solutions

The difficulty in this system lies in the measurement of high current, which directly affects the accuracy of the current source. This system uses a DC comparator to measure current and can quickly provide feedback on current changes. The time for establishing magnetic balance shall not exceed 1 μ s. The DC comparator has two types of errors: magnetic and capacitive. Magnetic error is caused by uneven magnetic permeability of the iron core, nonlinear magnetic characteristics, inconsistent iron core cross-sections, uneven distribution of primary and secondary windings, and the influence of external stray magnetic fields. The main magnetic shielding made of high magnetic flux density materials and the internal shielding made of high magnetic permeability materials can be used to reduce the error to 1 × 10-8. Capacitive error is caused by parasitic capacitance and potential differences between winding turns, windings, and windings to ground, resulting in corresponding leakage currents between them. Static shielding can be used to reduce errors. For measuring circuit errors, the main approach is to reduce the leakage resistance of the compensation winding. The compensation winding should be made of copper insulated wire with a larger cross-section to minimize the impact on the current measurement of the compensation winding. The broadband DC comparator is composed of double iron cores stacked and wound. IP is the DC high current, W1 is the excitation winding, W2 is the detection winding, and W3 is the compensation winding. Core A is made of high permeability soft magnetic material, while core B is made of low permeability ferrite material. Implementation principle: The excitation source excites iron cores A and B, and the W2 winding detection signal passes through a second harmonic bandpass filter circuit to detect the second harmonic signal. The DC signal is obtained through a demodulator and amplified by a preamplifier to control the output current of the servo current source to the W3 compensation winding. Through continuous adjustment, the iron core 1 and iron core 2 reach a magnetic balance state. The time for establishing system balance shall not exceed 1 μ s. Sample the current through the standard resistor R, test to obtain U, calculate the compensation winding current, and calculate the IP value based on the winding turns ratio. At the same time, this signal can be used as a status signal such as an alarm signal.

U = N×IP

In the formula: N is the proportionality constant

The Shitong Thermal Laboratory is mainly responsible for the measurement of temperature, humidity, and environmental tests; The Thermal Laboratory is one of the established laboratories of our company, equipped with standard temperature equipment from both domestic and international sources, such as FLUKE precision process calibrator, thermocouple calibration furnace, precision multi-channel temperature and humidity inspection instrument, high stability constant temperature and humidity calibration box, calibration level constant temperature bath, self calibrating high-precision platinum thermometer, thermal radiation source, etc; Due to long-term on-site experiments and calibration of environmental testing equipment, the technical personnel in this laboratory have rich experience in equipment debugging.

The types of instruments and equipment that can provide instrument calibration, instrument calibration, instrument measurement, and maintenance services are:

Temperature instrument:

Standard mercury thermometers, glass liquid thermometers, infrared radiation thermometers, bimetallic thermometers, electric contact thermometers, pressure thermometers, surface thermometers, semiconductor point thermometers, second-class platinum rhodium 10 platinum thermocouples, various working thermocouples, industrial platinum copper thermistors, standard constant temperature baths, tube calibration furnaces, dry and parallel calibration furnaces, temperature calibrators, surface temperature sources, various digital thermometers, digital thermometers, data collectors, temperature inspection instruments, soldering iron thermometers, temperature sensors, temperature transmitters, temperature indicator adjusters, temperature indicator controllers, temperature online instruments and meters, temperature parameters of various integrated instruments, etc.

Environmental testing equipment:

Constant temperature box, constant temperature and humidity box (room), various types of incubators, drying boxes, curing boxes (rooms), ovens, refrigerators, aging boxes (rooms), fast boiling boxes, salt spray test boxes, alternating test boxes, high and low temperature impact testing machines, climate (environment) testing machines, wet heat testing machines, sterilizers, water bath equipment, disintegrators, dissolution testers, digestion furnaces, resistance (muffle) furnaces, heat treatment furnaces, hot wire testing machines, combustion testing machines, temperature tunnels, reflux (peak) welding machines, heating tanks, injection molding machines, etc.

Humidity meter:

Various types of hygrometers, temperature and humidity sensors, psychrometers, humidity transmitters, humidity recorders, humidity generators, wood moisture meters, paper moisture meters, etc.