Electrical hazards are the primary factor causing building fires, and the importance of safe electricity management is paramount

Original title: Electrical hazards are the primary factor causing building fires. The importance of safe electricity management

summary

With the rapid development of the social economy, the frequency of building electrical fires is also on the rise, causing increasing losses to people's lives and safety. According to statistics, electrical hazards are the primary factor causing building fires.

The safety electricity management cloud platform launched by Ankerui Electric adopts independently developed residual current transformers, temperature sensors, and electrical fire detectors to continuously track and statistically analyze the main factors that cause electrical fires (wire temperature, current, and residual current), and timely push various hidden danger information discovered to enterprise management personnel, guiding enterprises to achieve timely investigation and treatment, eliminating potential electrical fire safety hazards, and achieving the goal of "prevention before it happens".

Users can access the platform by PC web page, mobile phone APP, WeChat applet, WeChat official account and other ways to query various information including system information, real-time data, alarm records, etc., which is convenient to use. By utilizing the low-cost professional services provided by this system to users, it can enhance the fire safety management and electrical equipment safety level of enterprises, prevent major malignant fire property losses, especially the occurrence of major malignant personnel injury liability accidents.

Application location

This platform is suitable for intelligent buildings, high-rise apartments, hotels, restaurants, commercial buildings, industrial and mining enterprises, fire protection units, as well as fields such as petrochemicals, culture, education, health, finance, telecommunications, etc. It is also suitable for small and micro places such as markets and stores to remotely measure, adjust, control, and signal detectors scattered in buildings, facilitating monitoring and management.

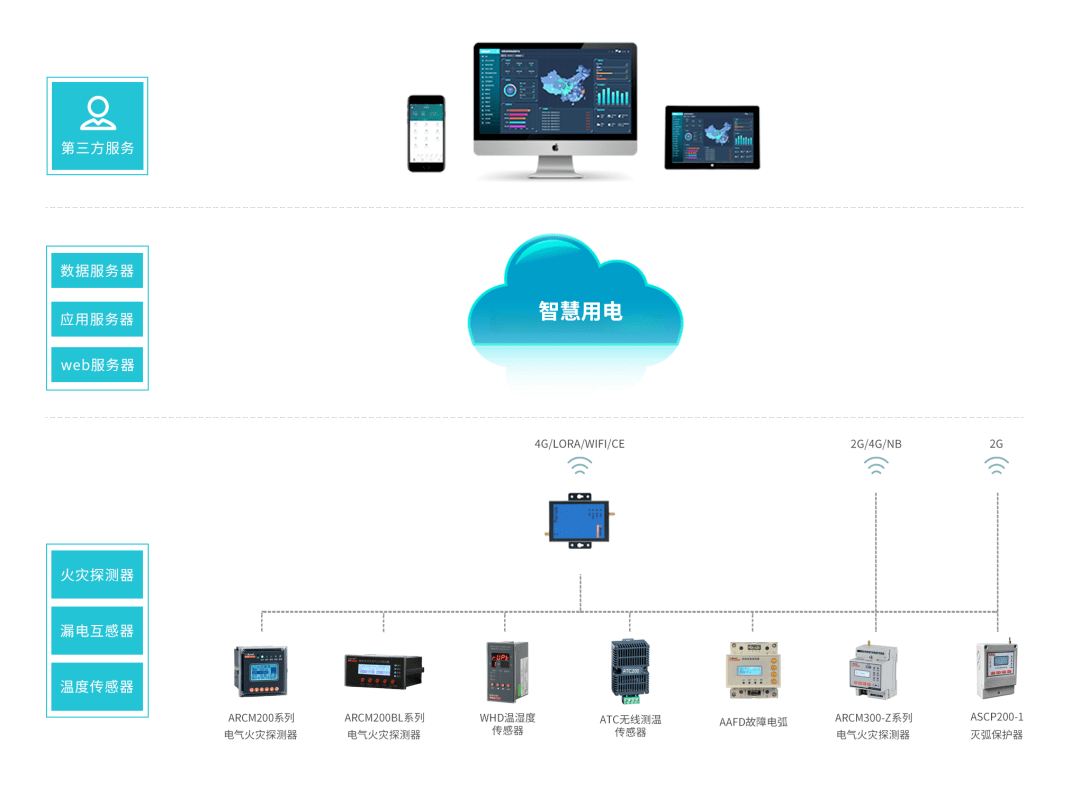

system architecture

The overall structure of this platform is shown in the figure:

system function

Real time monitoring

24-hour monitoring of residual current, temperature, voltage, current, harmonics, power, electrical energy, and other equipment status information at each detection point.

● Historical records

All alarm information and remote control are recorded in logs and can be easily queried by users.

● Data analysis

Conduct various model analyses and reports on the collected data to eliminate security risks for customers; Provide energy consumption analysis function.

● Alarm reminder

When the platform receives alarm or fault information, it will notify management personnel through SMS, phone or APP push, remind them to pay attention to the fault situation, and take corresponding measures to eliminate hidden dangers.

● Permission management

The platform implements hierarchical management of user types to achieve higher information security. Users with corresponding authorization can view, configure, and modify monitoring data and operation status of projects, devices, detectors, etc. within the authorized scope.

● Remote control

Authorized management personnel can remotely set various parameter values of detectors, or perform operations such as opening, resetting, muting, self checking, and remote parameter setting on monitoring equipment, which facilitates management and improves work efficiency.

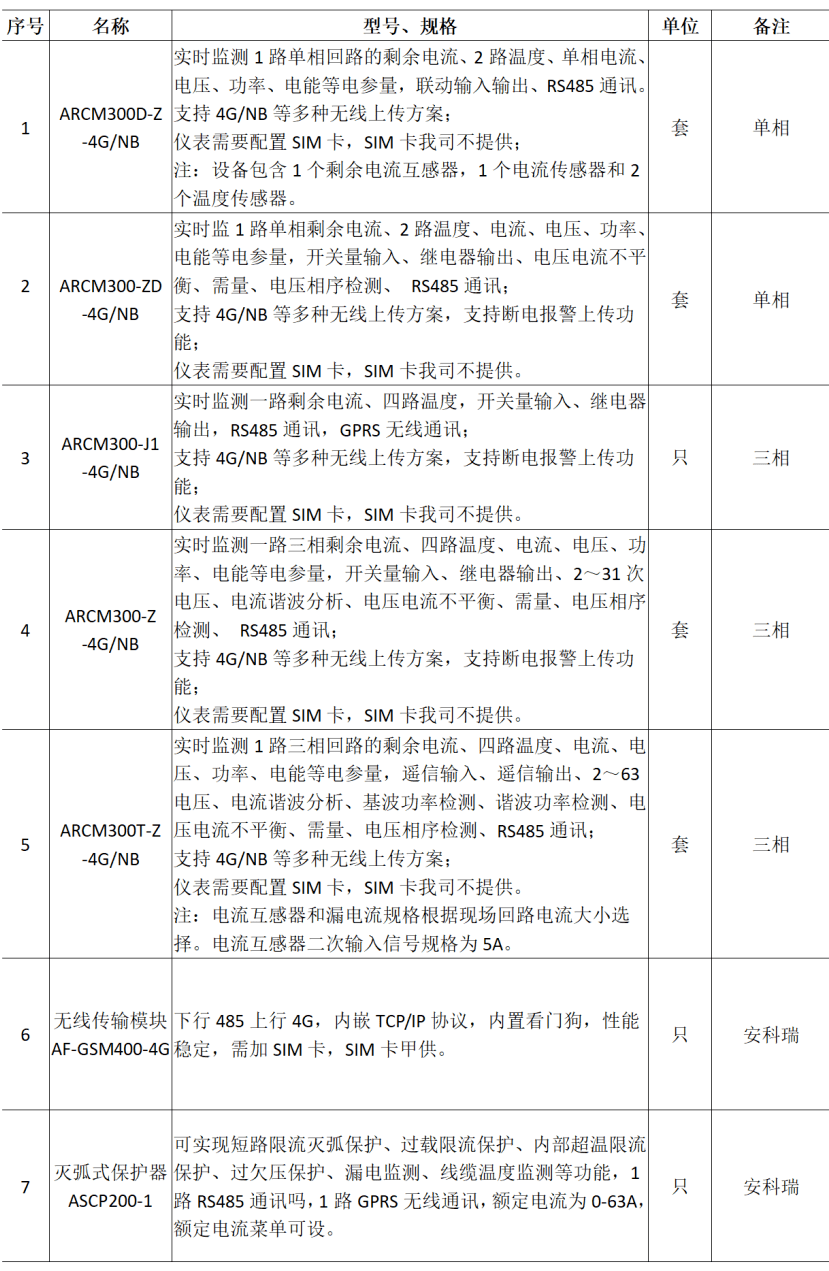

Product selection

Typical configuration scheme

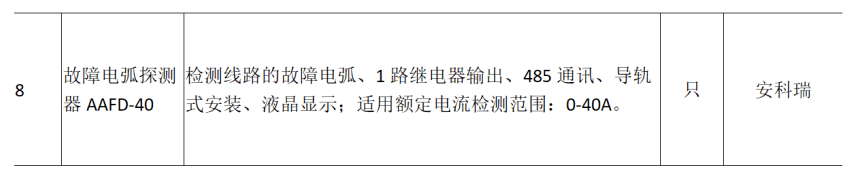

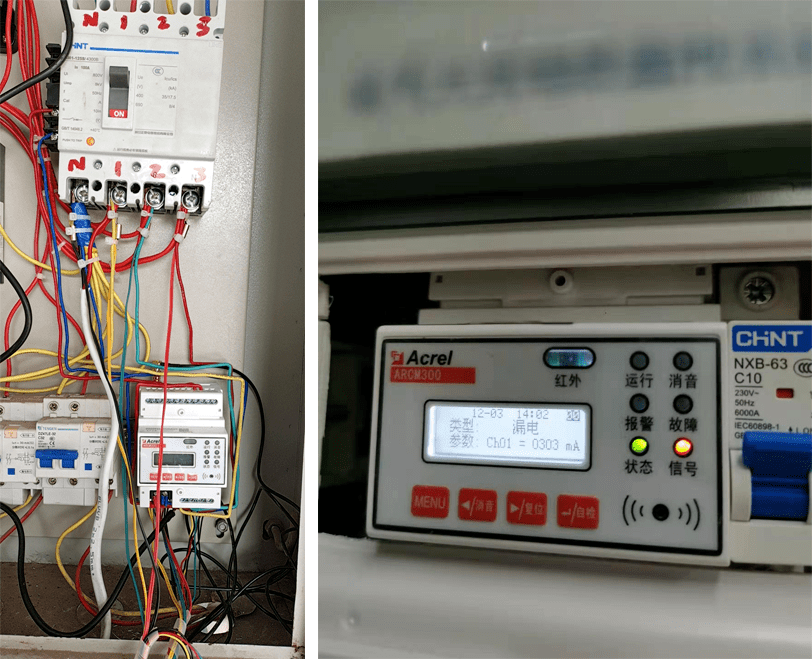

ARCM300 series instrument direct connection platform

a) Configuration plan

Explanation: ARCM300-Z-4G and ARCM300-ZD-4G are directly uploaded to the platform.

b) Install instance

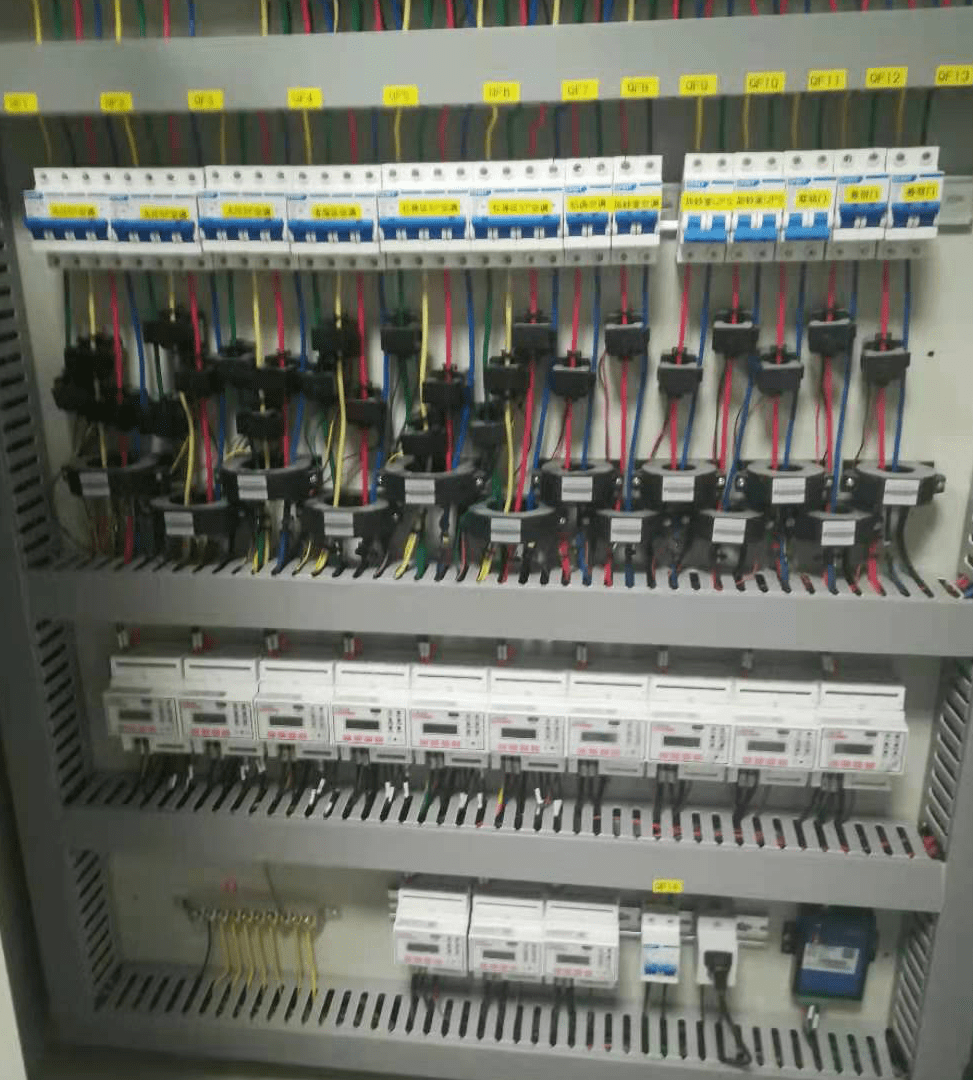

Upload ARCM300 series instrument access gateway to the platform

a) Configuration plan

Explanation: The ArcM series instruments are connected to a gateway through a 485 interface and uploaded to the platform through the gateway. 30 instruments can be connected to one gateway

b) Install instance

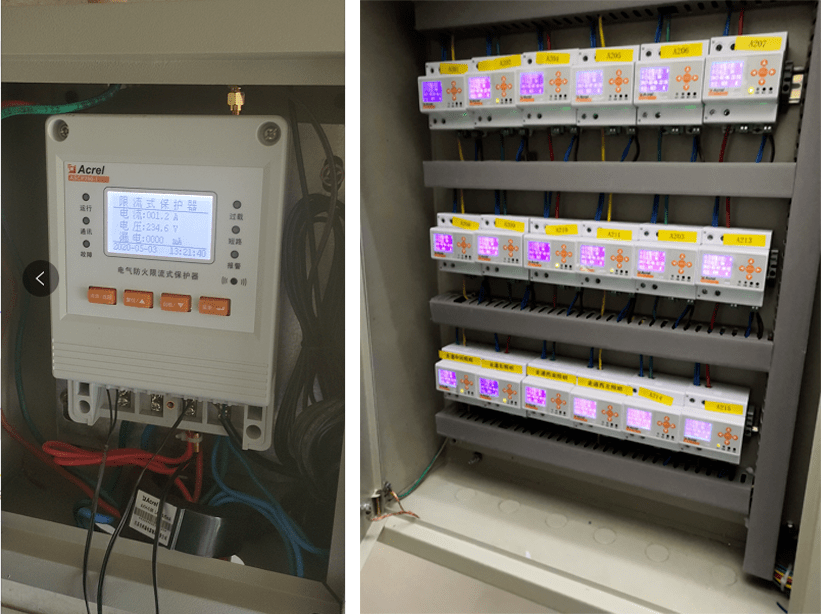

● Fault arc detector and arc extinguishing protector access platform

a) Configuration plan

Explanation: The fault arc detector and arc extinguishing protector are connected to the gateway through a 485 interface, and uploaded to the platform by the gateway. 30 devices can be connected under one gateway.

b) Install instance

classic case

China Railway Group's Safety Electricity Management Cloud Platform

Yunnan Yuxi Electric Power Safety Management Cloud Platform

Smart Electrical Fire Monitoring System for Compulsory Drug Rehabilitation Center in a Certain Area

Xiangshui Livestock Renovation Safety Electricity Management System

Tianjin Electronic Co., Ltd. Safety Electricity Management Cloud Platform

Cloud platform for safe electricity management of a glacier relic exhibition hall

Chengde Network Technology Co., Ltd. Security Electricity Management Cloud Platform

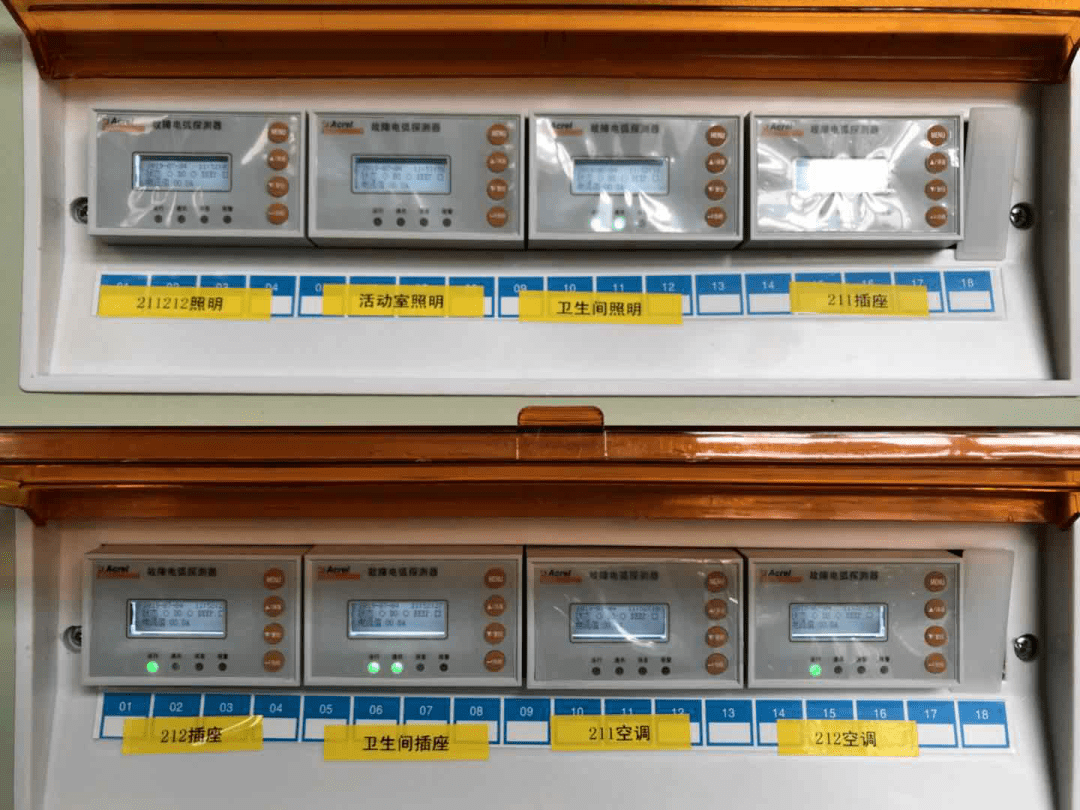

Safe use of electricity in a campus of Fudan University

Guangdong Energy Technology Co., Ltd. Safety Electricity Management Cloud Platform

Hunan Smart Fire Technology Co., Ltd. Safety Electricity Management Cloud Platform

: